What do you enjoy most about your role?

I think it’s a cliche that people often say “Every day is different”, but in what is quite a small business at the moment, it is true for me. Every day is very different, and it’s really broad so I’m a chemist by training, but I’m involved in all sorts of things now that I wouldn’t normally get involved with, in a bigger business.

What excites you the most about Sonichem?

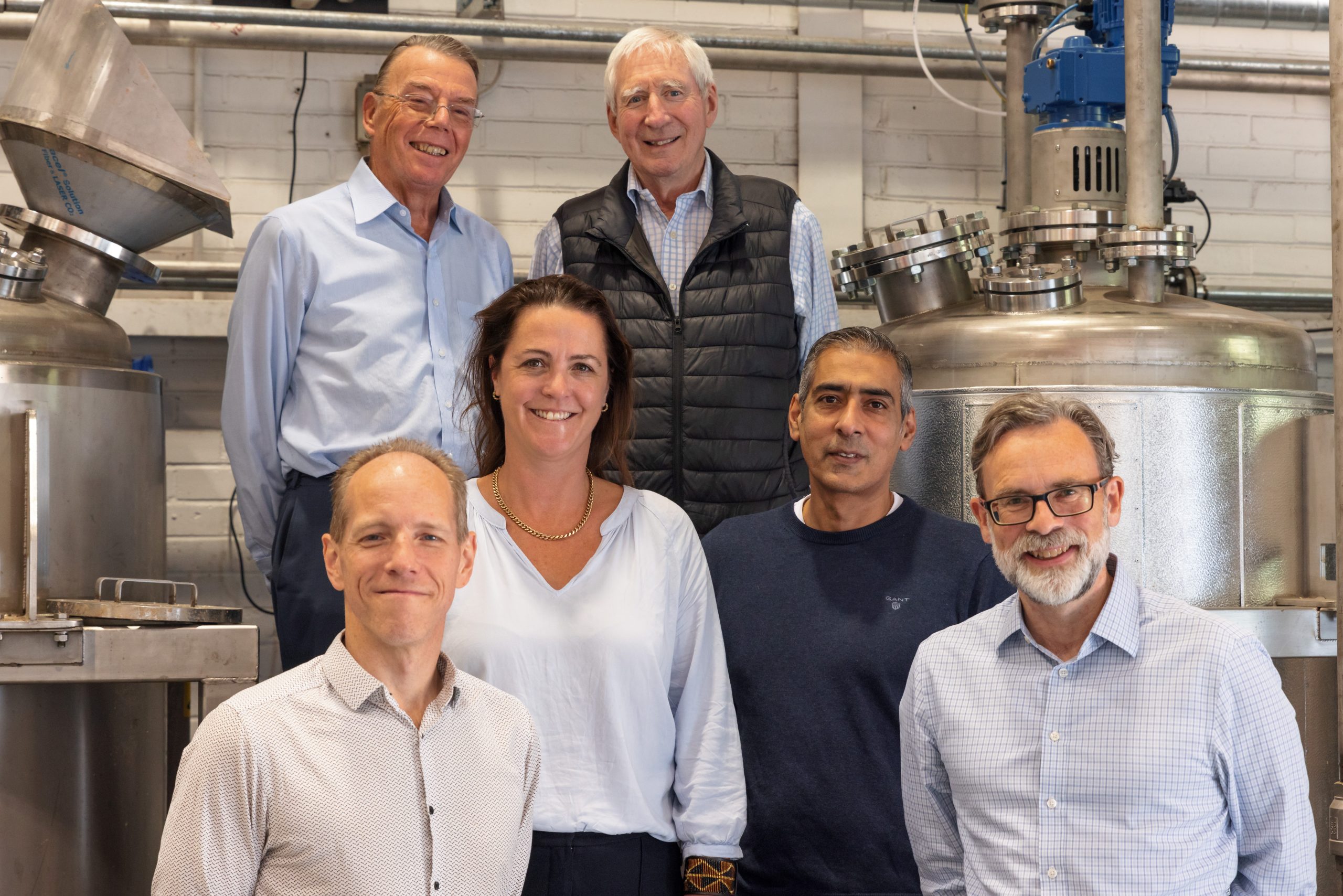

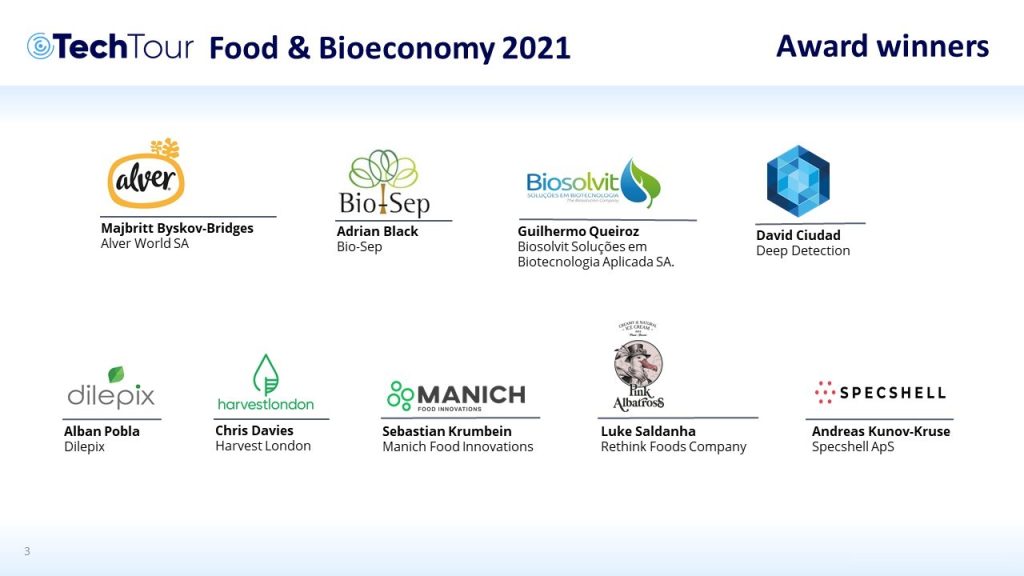

Sonichem (formerly Bio-Sep) is on a very interesting journey. The opportunity to work in lots of different areas is fascinating for me from a company point of view.

What’s also exciting is that the technology that we’ve developed over time is completely novel. There isn’t anything else like it on the market, and the impact this technology could have on the world in terms of reducing carbon emissions, saving cost and import substitutions and helping people is really exciting.

It’s a very interesting technology. So for a chemistry geek like myself, it is a great business to be involved in.

The journey of the company means that this is something that I think is going to grow from a small company based in the heart of England, to something that could be national, international, and much, much bigger.

Let’s talk about the carbon emission piece because I think that’s very topical at the moment, could you explain how Sonichem technology helps reduce carbon emissions?

An awful lot of the materials that we’re looking to process would currently be either burnt or sent for landfill and all of that carbon that’s been embedded in those products, so things like wood waste or municipal solid waste will get lost over time, released into the environment.

Natural degradation or burning will release all of that carbon that’s trapped within those materials into the environment. The Sonichem process turns all of that embedded carbon into useful products.

So platform chemicals and materials can be used after processing to replace crude oil-derived products. It means all of that carbon remains trapped within the product rather than being released. As a result, there are multiple benefits from the process including things like the cost of transporting, the cost of importing chemicals, all kinds of perfect substitutes.. We’ve got that ability to use materials that would otherwise be effectively lost as waste. These represent powerful benefits of the technology.

Can you explain how Sonichem (formerly Bio-Sep) could help with municipal waste?

There’s a lot of waste materials that are sent to landfill, not because they’re not of high quality or because they couldn’t be reused but simply because of the way that legislation works.

So, for example, materials that have been in contact with food are always sent to landfill because the risk of contamination is too high for them to be recycled. Our process would make sure that anything that went through it was completely sterilised before it came out the other end.

And then fractionated into all of those useful materials, so say lamps from cardboard, lignins also from cardboard and other materials that we would then be able to reuse, without the fear of that contamination problem.

What types of applications would the Sonichem process feed into?

The materials could be used as ‘drop in’ replacements in some industries but we’re quite excited about the fact that these compounds can all be further processed into materials that people would use in everyday life. So they could be used in pharmaceuticals, they can be used in cosmetics. They could be used in food and flavours and fragrances so you could have them as sweeteners, natural sweeteners or they could be converted into flavours like fruit flavours or all the things that people would have in their daily lives.

At the other end of the scale, we can go into things like construction so we can use in glues resins and paints, we can use them as fillers in cement concrete which reduces the number of imports, we have to bring into the UK on fillers and that’s a really big market and there’s a huge need for that.

The lignin component can be used on road surfaces, so you can use this as an extender for bitumen.

It is a very broad spectrum of things that we could use these materials in; clothes, paper, face cream – there are a huge number of applications for these materials.

There is a lot of research going on in, in these materials as you’d expect, because they haven’t been widely available, until very recently, also not in pure form, and the sort of research you’re looking at includes all the wooden materials, graphene, nanofibers, and nano fibrillated cellulose which has all sorts of pharmaceutical applications. So they’re really nice but very very high value. There is also the potential to allow these materials to be less niche which is important for things like graphene or carbon nanotubes and those materials that have a huge promise but aren’t widely available yet.

What type of partner is likely to find what Bio-Sep (now Sonichem) offers of interest?

The partners are both front end or upstream and downstream.

So we’ve got companies who are making those resources so let’s say it’s forestry, or it might be local government if it’s just for solid waste storage. It might be industry producers or other lignocellulosic type materials. So that’s the front end part.

The downstream element is pharmaceutical companies, food and flavour companies, those working in construction materials, glues and resins and so on.

Some of the more niche applications are working with other SMEs who are doing some really exciting research into what we might use these materials including high-value pharmaceuticals, nutraceuticals and drop-in replacements for resins and fire retardants.

There’s a whole host of different applications, and we’re selecting those ones that we think are easy wins and therefore will support the business in the short term, with the vision to have those more long term high value wins further down the line.

How do you view the next few years at Sonichem?

There’s a huge amount to do. It’s very exciting because this is very, very different to be in a business that has so many options and so many opportunities. The next big next step for the company is to build a large scale unit, processing about 20,000 tonnes a year. That will probably be in Scotland. We can then demonstrate at scale that we can make these products constantly and consistently. Consistently is a really important part because there’s an awful lot in competing technologies as normal, often variability in products, and we want to be certain that our preliminary results that demonstrate this are consistent and can be carried out at scale to customers.