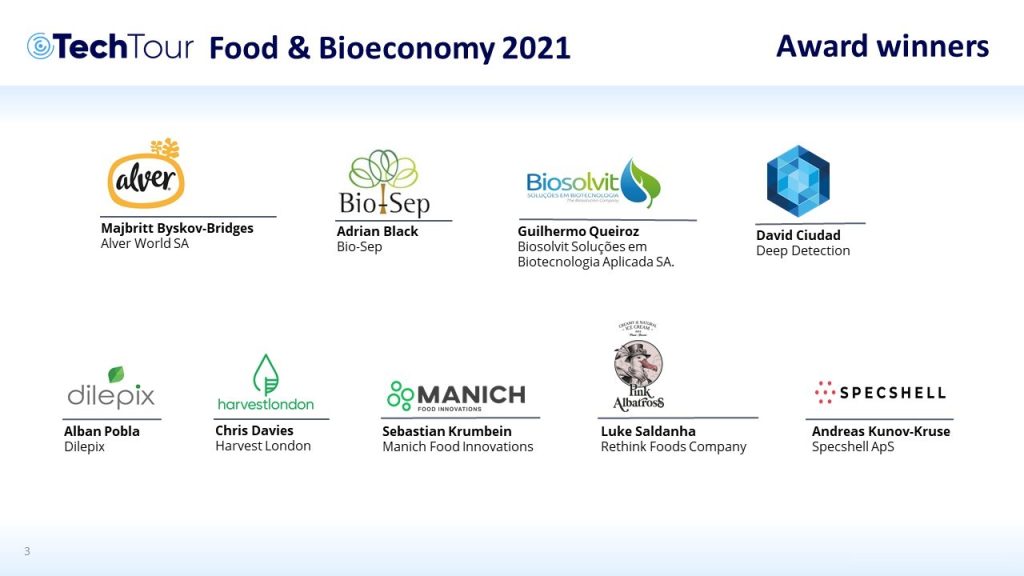

Bio-Sep secures $1.7 Million for our green-tech that turns sawdust into sustainable biochemicals, from investors including London Business School’s Enterprise 100 investment club and ACF Investors, with additional participation from a hedge fund that specialises in climate and clean energy technology.

As a society, we rely heavily on the chemicals industry. Products produced by chemical companies afford us high quality of life – they’re the backbone of everything from modern healthcare to technology. But it’s also an industry that’s notoriously polluting. Cleaning up and decarbonising the chemicals industry will be absolutely key if we are to meet climate goals like the Paris Agreement, and the technology provided by Bio-Sep is well-placed to play a central role.

Sam Fennel, Partner at ACF Investors Tweet

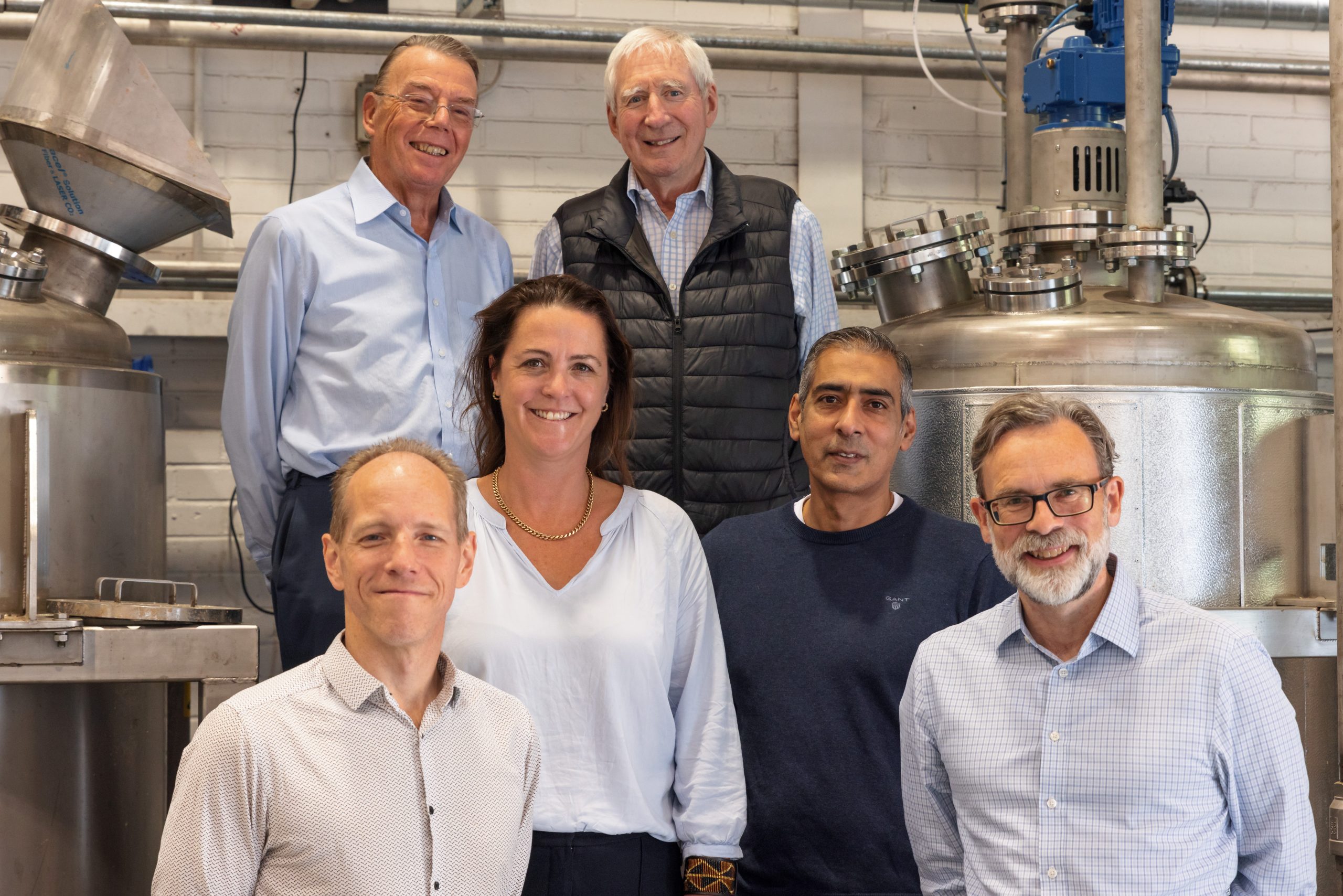

Bio-Sep's Story

Bio-Sep was founded by Stephen Brooks, a sugar chemist, who was trying to find a solution to the waste from sugar cane production, where 30% of the plant is waste woody biomass which is generally burned or left to rot. Bio-Sep has developed and patented a cleaner, low-energy solution that uses ultrasound to help break down woody biomass into high-value biochemical products.

Bio-Sep is currently upcycling sawdust, which is the most widely available woody biomass in the UK, from forestry partners. Each £1 of sawdust from sawmills is transformed into £6 of biochemicals with a broad range of potential uses. These biochemicals can often be used to replace petrochemicals, contributing to the decarbonisation of the chemicals industry.

Sustainable Biochemicals

- Microcrystalline cellulose – a well-known speciality chemical found in medications, cosmetics, composites and 3D printing

- Natural lignin – a complex aromatic polymer that is the only natural substitute for a petroleum-sourced chemical known as phenol which offers a huge number of business opportunities to be used for bio-based resins, composites, coatings, polyurethane foams, bioplastics and more.

- Hemicellulose hydrolysate – a mixed sugar syrup that can either be used as a syrup or further processed into sugar alcohols, such as xylitol and sorbitol frequently found in dental products, pharmaceuticals, food and beverages

Adrian Black, CEO

Our technology takes a low-value agricultural or forestry co-product and turns it into essential chemical building blocks, with all manner of applications across the chemical industry and beyond, delivering significant environmental and economic benefits. This investment will enable us to push on and commercialise the technology and is a fantastic show of support for what we believe to be a world-changing innovation.

Adrian Black, CEO Tweet

The funding will be used to recruit staff to operate the pilot plant at our facility located in the Midlands and design the first scaled-up, commercial plant planned for development in heavily forested Scotland. Construction of the commercial plant, which will be able to process approximately 13,000 tonnes of wood a year, is set to begin in 2023.

The Enterprise 100 Club has provided a vital pipeline of funding for budding startups at London Business School, giving them the opportunity to scale their businesses over the last 22 years and injecting new blood into the School’s ecosystem. I look forward to seeing Bio-Sep reaching new heights with this funding.

Jane Khedair, Director of LBS’ Institute of Entrepreneurship and Private Capital Tweet