The Green Revolution

Carbon is the backbone of so many everyday materials and products that the chemical industry producing these products accounts for around 6% of global petroleum use. Societal concerns around climate change and decarbonization are driving what industry and policy makers are calling the Green Revolution, a movement in manufacturing from black petro-sourced carbon to green bio-sourced carbon.

Global brands including Unilever, PepsiCo and L’Oreal are investing billions of pounds to remove fossil-derived ingredients from their products and packaging over the next 5-10 years, significantly increasing demand for bio-derived alternatives. However, with natural resource depletion, increasing strain on global supply chains and an ever-growing global population, there are significant sustainability concerns regarding the use of food crops in chemical production. Focus instead is shifting towards the use of low value co-products from agricultural and forestry operations as a more suitable source of biochemicals.

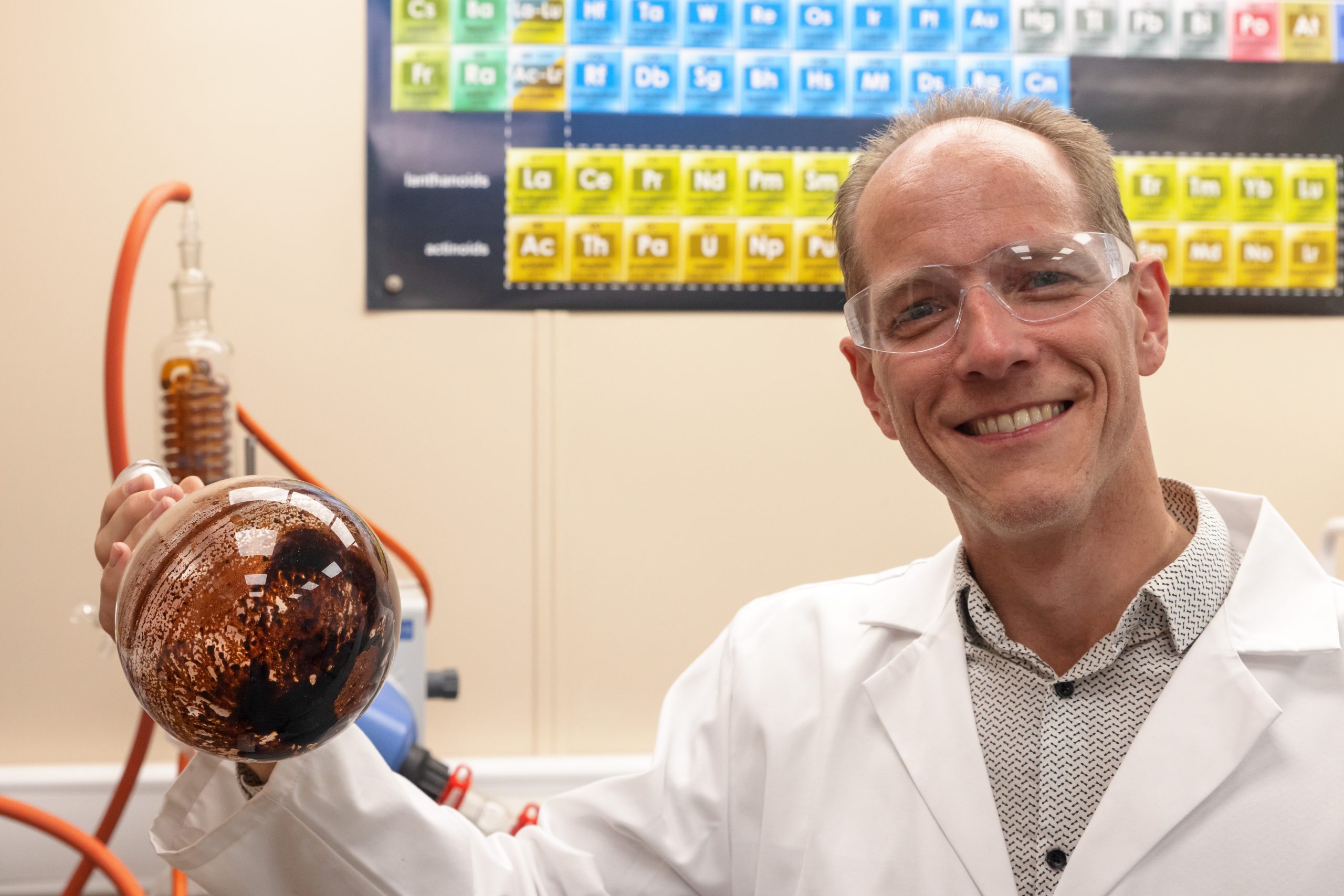

Against this backdrop, Sonichem’s mission is to maximise the value of underutilised resources. To achieve this, Sonichem have developed Sonichem an award-winning low-energy ultrasonic process to convert woody biomass into chemicals. The Sonichem process generates almost zero waste, is water-use neutral, and produces three high-value products (cellulose, sugar syrup and lignin).

Wood: Nature’s Composite

The fibrous or woody component of plants and trees is called lignocellulose. The word derives from ‘Lignum’, the Latin name for wood, and is essentially nature’s composite. Wood consists of three components: cellulose fibres together with hemicellulose form a matrix which in turn is bound together by an aromatic biochemical called lignin. In nature this complex chemical structure of three biochemicals results in a solid cell wall that is resistant to wind, water, pests, and sunlight. When separated from each other these biochemicals are known as bio-based platform biochemicals and have wide market potential.

For many years, cellulose has been extracted from wood for the pulp and paper industry. Bio-Sep’s ultrasonic process produces a crystalline cellulose which is a high value speciality chemical with applications in food and beverages, cosmetics, and performance composites.

Lignin is the world’s second most abundant biopolymer after cellulose. It is nature’s binding material, the substance that gives plants and trees their structural integrity and strength. Its aromatic structure makes it the most suitable biochemical to replace a toxic petrochemical called phenol, which is commonly used in resins, composites, coatings, and adhesives. Fluctuations in the price of phenol due to changes in oil price, and concerns about the toxic exposure of workers to phenol during the manufacturing process, make lignin an attractive bio-derived alternative. Natural lignin could be used for a phenolic replacement to make sustainable resins for use in, for example, the chipboard industry; the chips of wood could be held together with a resin made from lignin. Lignin as an eco-substitute not only reduces the carbon footprint and toxicity for manufacturers but also provides additional performance benefits such as fire resistance and UV protection.

The UK’s composite challenge is an opportunity

Humans have been making composite materials for years, starting thousands of years ago with a mud brick made from mud and straw, evolving to today’s materials such as concrete –a matrix of small stones bound by cement and lightweight materials such as carbon fibre.

Composites are a high growth industry in the UK across sectors such as construction, aeronautics, and now renewable energy with wind turbines being made in the UK. Composites UK estimates the UK composites industry was valued at £16.64bn in 2020. Added to this, UK composites companies are increasingly focused on biomaterial use for their sustainability strategy. According to Innovate UK, a lack of local supply of these biomaterials is one of their biggest challenges.

Supply chain issues over the last few years combined with the environmental footprint of shipping means that the industry is clamouring for a ‘reshoring’ of their input materials. This challenge to the composite industry presents a huge market opportunity for suitable platform biochemicals. This includes lignin and cellulose produced in the UK from available biomass sources, the most abundant of which is sawdust from the forestry industry.

R&D for a new forestry based performance composite

Sonichem embarked on a Joint Industry Project together with iCAST (The innovation Centre of Applied Sustainable Technologies), the National Composite Centre (NCC), and the University of Bath for the production and testing of bio-based composites from cellulose and lignin. Market testing will be undertaken by Scott Bader, a global manufacturer of resins and composites.

The NCC are looking to enhance their experience and understanding of the properties and manufacture of novel, sustainable materials

For this project they will be testing the mechanical properties and performance of Sonichem produced lignin and cellulose blends as a composite binder/matrix material.

The University of Bath will be producing and testing concrete materials incorporating Sonichems products as admixtures. Early results from the project are looking promising with demonstrable performance benefits and carbon reduction potential.

This project will enable the identification of construction and composite applications for lignin and cellulose extracted from UK grown sawdust (generously supplied to Sonichem by James Jones & Sons). With tried and tested performance characteristics, the high growth UK composites industry could make use of these low carbon, renewable materials, to displace petrochemical materials, create a local biochemical supply chain, and enhance the sustainability of their products.

Q&A

How do you see biorefining contributing towards net zero in the next 10-30 years?

The world needs chemicals, plastics, composites, and household goods that are not derived from crude oil, with its unsustainable impact on the environment, or from food crops, but instead from sustainable sources such as forestry. Biorefining will enable a shift from fossil to renewable green carbon resources, helping decouple chemical production from fossil resources and reducing CO2 emissions.

Is there an appetite from manufacturers to shift processes to using natural biochemicals?

Absolutely. Manufacturers cannot see a future without sustainable chemicals. Consumer behavior and government regulations such as carbon taxes will drive the change. In the future it is unlikely that chemicals will be purchased without a life cycle analysis, carbon footprint analysis and traceable supply certificate.

What of Sonichem’s current work are you most excited to see the results from?

I am really looking forward to seeing the results from the aforementioned industry project where we will be producing and testing a composite product. We also have another project in the pipeline which will look deeper into lignin as a coating. I can see a future where we produce a waterproof, fire-resistant composite out of 100% forestry-produced biochemicals that can be recycled again by our process at end-of-life to create something new, resulting in truly circular green materials.